Essential roles and responsibilities in a warehouse (updated 2024)

.png)

Warehouses are vital hubs in the supply chain, ensuring goods are efficiently stored, managed, and distributed. A well-run warehouse depends on the coordination of key roles, each contributing to smooth operations and productivity. Understanding these roles in detail is essential for effective management.

Read more: Discover how WMS systems enhance warehouse operations in our article "What is WMS?"

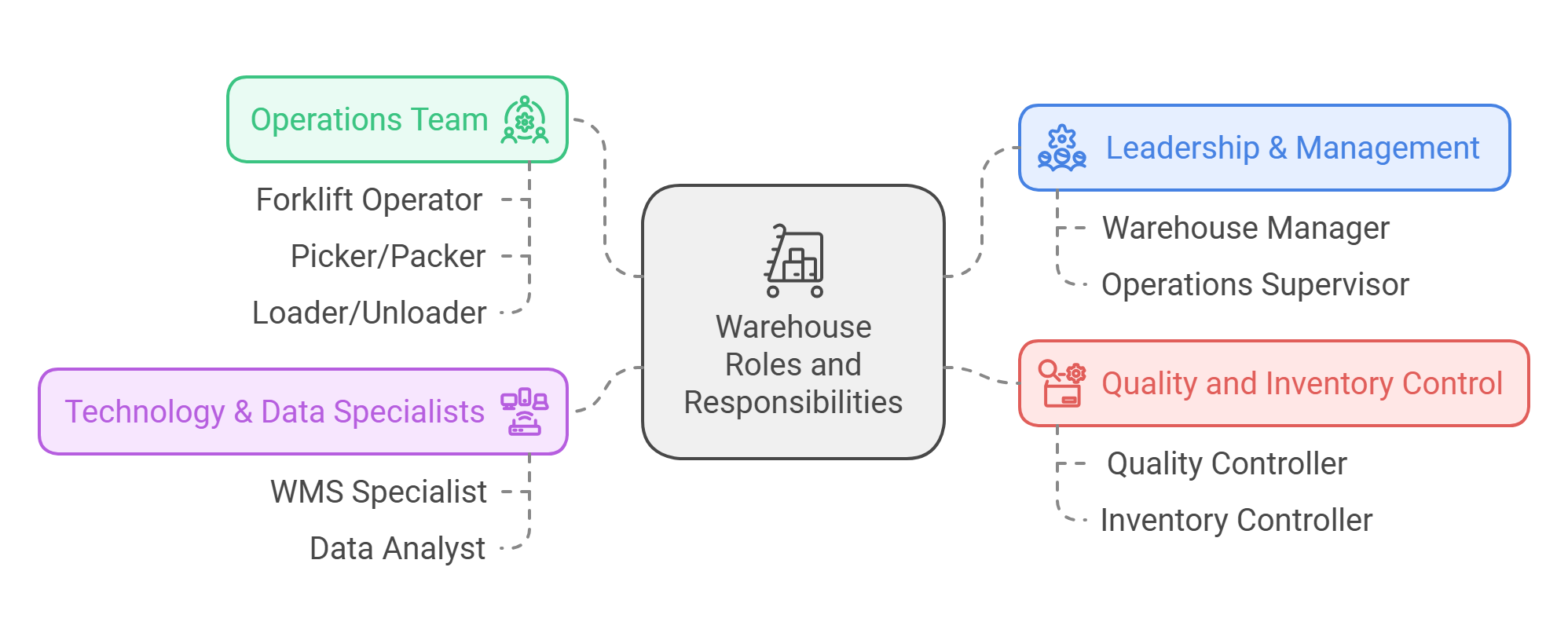

Organizational Structure

A streamlined warehouse structure fosters efficiency and accountability. Below is a basic organizational chart to illustrate the hierarchy:

Key Roles and Their Responsibilities

1. Leadership & Management

Warehouse Manager:

- Develops operational strategies to meet business objectives.

- Monitors performance metrics like order accuracy and turnaround times.

- Ensures compliance with safety and regulatory standards.

Operations Supervisor:

- Oversees daily workflows, assigning tasks and resolving bottlenecks.

- Coordinates with different departments to ensure timely order processing.

- Addresses staffing issues and monitors team productivity.

2. Operations Team

Forklift Operator:

- Operates machinery to transport heavy goods and materials safely.

- Inspects forklifts for maintenance issues before use.

- Organizes goods for easy retrieval and efficient space utilization.

Picker/Packer:

- Reads order slips and retrieves items accurately.

- Packs goods securely for shipment, adhering to packing guidelines.

- Conducts quality checks to ensure item correctness before dispatch.

Loader/Unloader:

- Manages the loading and unloading of shipments manually or with equipment.

- Inspects goods for visible damage during the handling process.

- Ensures items are stored in designated locations promptly.

3. Quality and Inventory Control

Quality Controller:

- Conducts detailed inspections of inbound and outbound goods.

- Ensures packaging integrity and adherence to quality standards.

- Reports defects and coordinates with suppliers for resolutions.

Inventory Controller:

- Monitors stock levels using inventory management systems.

- Conducts regular cycle counts to maintain inventory accuracy.

- Resolves discrepancies and updates records accordingly.

4. Technology & Data Specialists

WMS Specialist:

- Implements and maintains the Warehouse Management System (WMS).

- Trains staff on WMS functionalities for smoother adoption.

- Troubleshoots system issues and ensures data integrity.

Data Analyst:

- Compiles operational data to identify trends and inefficiencies.

- Recommends actionable insights to optimize warehouse workflows.

- Tracks KPIs such as order accuracy and processing times.

Common Challenges in Warehouse Management

- Role Overlaps: Lack of clarity can result in inefficiencies and duplicated efforts.

- Technology Resistance: Employees may struggle to adapt to WMS or other digital tools.

- Labor Gaps: Difficulty in recruiting skilled workers impacts productivity.

- Inadequate Training: Poorly trained staff lead to errors and potential safety hazards.

A well-coordinated warehouse team is essential for efficient operations and high productivity. Understanding key roles and addressing challenges like training and labor shortages ensure seamless performance. Tools like WMS play a pivotal role in integrating and enhancing these processes.

Ready to streamline your warehouse operations? SellnShip’s WMS offers the solutions you need. Explore our WMS now!